The parathermtm heat transfer fluid technology are thermally stable fluids with an alkylated aromatic Based heat transfer fluid formulated for closed-loop liquid-phase heating systems to 550°F; Chemical equivalent and compatible with major heat treat fluid technologies.

ParathermTM Heat Transfer Fluids are a thermally stable fluid that exhibited almost 40% less degradation when exposed to 600°F (316°C) for 500 hours than a widely used competitive fluid. Although very few heaters expose the fluid to the maximum film temperature for extended periods, this level of stability helps ensure that your system operates trouble=free during operating upsets.

Minimum startup temperature is a realistic measure of a thermally stable heat transfer fluid’s low temperature capability since 300 cps is the maximum viscosity that a centrifugal pump can handle. Paratherm TM GLT Heat Transfer Fluid has a lower minimum start-up temperature 18°F (-6°C) than any mineral-oil based fluids that cover a similar temperature range.

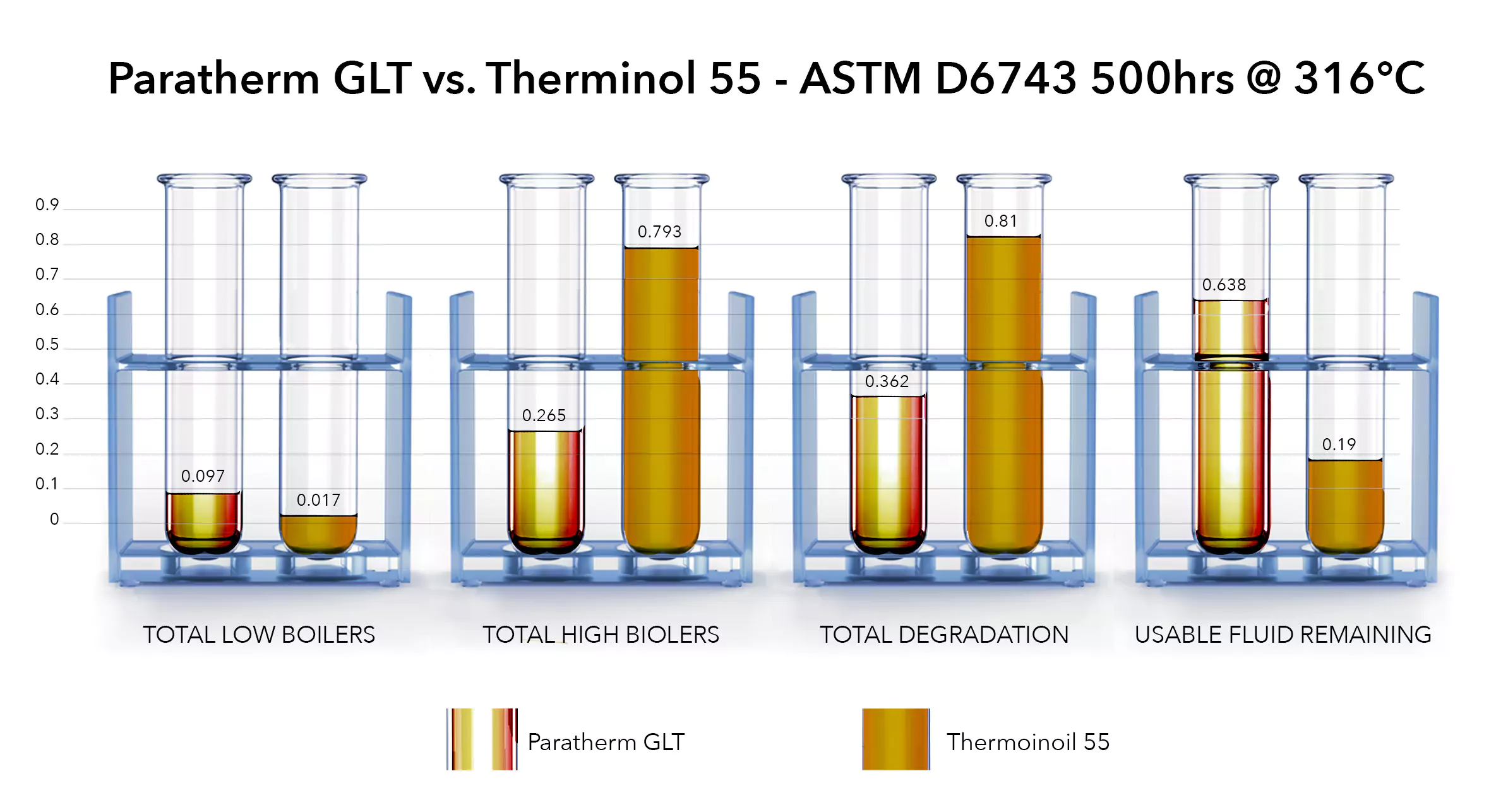

Performance Data: Paratherm TM GLT vs. Therminol 55

ASTM D64743 – Thermal Stability of Organic Heat Transfer Fluids

Fluid samples held at 316°c ·600F for 500 hours to assess stability to continuous thermal stress. The total degradation is determined by the total mass percentage of high boilers, low boilers and other decomposition products found in the thermally stressed sample. This value reflects the overall thermal degradation of the stressed fluid as a direct result of thermal stress.

A lower degree of decomposition is directly proportional to the overall thermal stability of the heat transfer fluid relative to other samples tested under the same conditions.

Side-by-side testing of Paratherm TM GLT vs. Therminol 55 provides evidence that the GLT thermally stable heat transfer fluid has significant advantages under demanding operating conditions. The primary contributing factor to the total degradation of alkylated aromatics is the high boilers. High boiling degradation by-products are polyaromatics that lead to sludges, tars, and varnishes, and a complete change in physical properties. High decomposition rates have a significant impact on the designed performance of the fluid and will increase the potential for lost production, shortened equipment life and frequent clean-out procedures due to fouling

Parathermtm glt exhibits superior stability with nearly half the total degradation experienced by therminol 55 under demanding conditions. *therminol 55 is a trademark of eastman chemical company.

Comparison of paratherm tm glt with therminol 55*