With so many different product options out there, how do you choose the best lubricant for your application? Fluid Dynamics CPI product line has a full range of products for rotary screw, rotary vane, reciprocating and centrifugal compressors with field proven performance to provide you with peace o mind. We work closely with major original equipment manufacturers (OEM’s) to offer a wide range of products tha meet key criteria for optimal compressor performance including:

Our knowledgeable technical sales staff will help you navigate the extensive Fluid Dynamics portfolio to choose the right product for your application. Fluid Dynamics and CPI technical assistance doesn’t stop there. Fluid Dynamics and CPI’s in-house oil testing provides used oil analysis with 48-hour turnaround to ensure your equipment is running optimally. Our experienced report writers analyze your results and compare them to your fluid’s used oil specification and previous samples. As the fluid developer, CPI’s technology is fomulated to meet the exact standards of air compressor OEM manufacturers

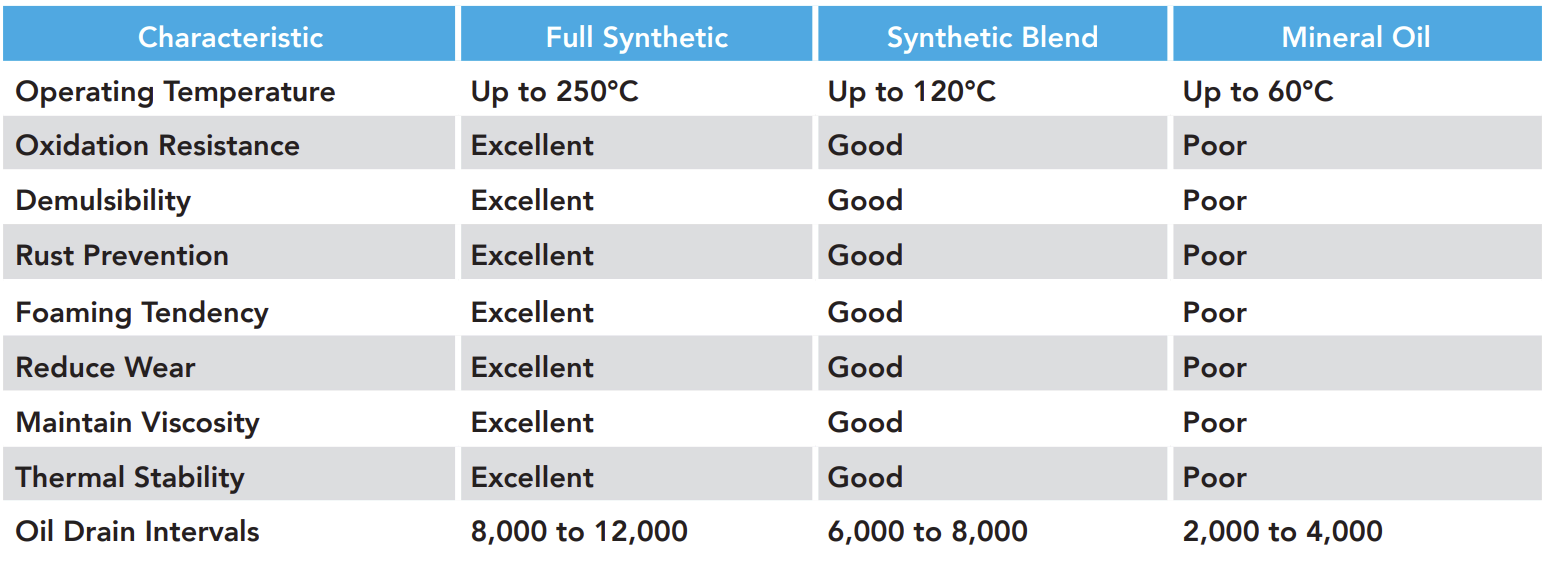

Synthetic lubricants proide improved performance over mineral iols and synthetic blends. Key performance characteristics for air compressor lubricants are shown in the table.

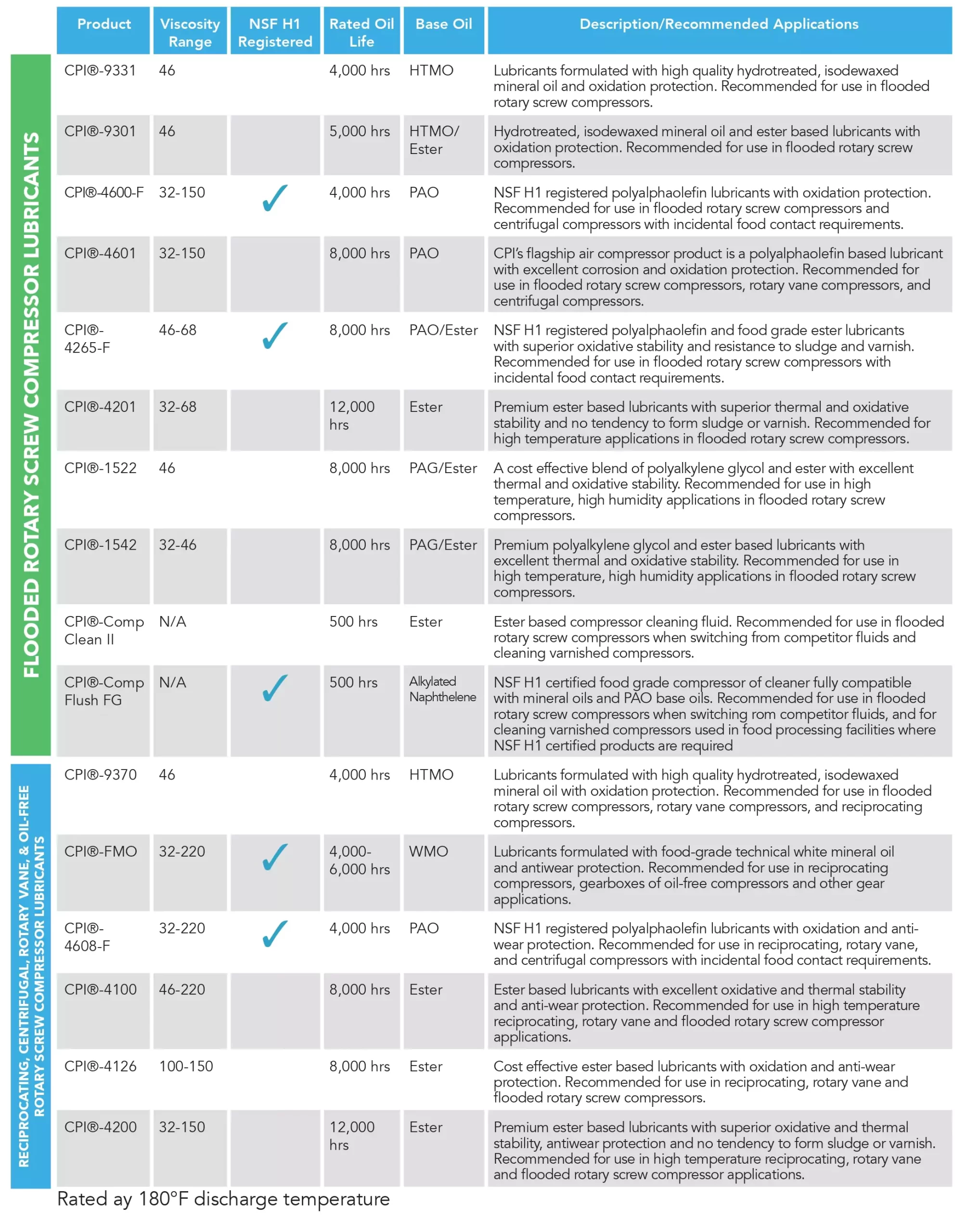

Fluid Dynamics’ CPT Line of air compressor lubricants offers a complete range of chemistries to meet the needs of your application and ensure the long-term performance of yor equipment. Our range of lubricants includes products fo flooded rotary screw, recriprocating, rotary vane, and centrifugal compressors